We built an extremely small and easy-to-use desktop size plastic injection machine and were calling it. The unit itself measures approximately 12 inches long x 1-34 inch diameter at its widest point and weighs just 3 pounds.

Home Injection Molding Injection Moulding Plastic Injection Molding Plastic Moulding

On average injection molded parts should have a wall thickness that ranges from 008 2mm to 016 4mm but thin wall injection molding can go as thin as 002 05mm.

. The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity. Place the side with the sprue and air holes face up. A second employee enters the point of operation to retrieve completed parts from the mold.

How to Specify an Injection Molding Machine. Read on to see the best DIY and desktop injection molding machines. Watch Out Hobbyist 3D Printing â Here Comes DIY Injection Molding.

But wall thickness also depends on the material used. Instructions for building one also are on the Action Box channel. LNS Technologies Model 150A.

You wont need a machine shop at home and you can even build the mold itself using a DIY CNC machine. C Clamp the mold in place by turning the vise handle clockwise. A 1500 hand-operated bench-model plastic injection machine funded via Kickstarter can be used to mold small quality plastic parts inexpensively on demand.

Based on the part that was molded estimate or measure the amount of plastic resin needed to. Connect via private message. Is creating DIY and Crafts Videos Animations and More.

Unlock 343 exclusive posts. Become a patron to. Inexpensive homemade molds can be made using an epoxy or urethane resin.

The Crafsman - Steady Craftin. A Place a mold in the machine. Injection molding machine press the melted plastic into the mold and cool down by cooling system into solid designed shape almost all thermoplastics using this method comparing with other processing way injection molding has advantage of accuracy productivity it has higher.

Or by machining a desired cavity into an aluminum. As luck would have it you can get a nice-looking pneumatic press for less than 350 and with a little more money spent Kurt found he could convert it into a functional injection molding. Jim Fattori is a third-generation injection molder with more than 40 years of molding experience.

DIY Injection Molder Buster Beagle 3D. Shown here is the prototype with the basic manual screw tightening mold vise that comes stan. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle.

With the market percolating more molders are looking at new presses. About seven years ago PlasticsToday published an article about a tabletop injection molding machine the 20A PIM-Shooter developed by LNS Technologies Scotts Valley CA. The economic upturn is bringing the injection molding manufacturing market along for the ride.

The injection molding is a process to form the plastic resin into the desired shape. In operation plastic is melted in the injection barrel of the machine by two 14 inch diameter x 2-12 inch long cartridge heaters. This series will discuss what you should consider before writing a check beginning with the clamping unit.

3200 ton horizontal injection mold press. He is the founder of Injection Mold Consulting LLC and is also a project engineer for a large multi-plant molder in New. DIY desktop injection molding is finally a reality.

Given the enduring interest in this piece of equipment we thought it. Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or moldInjection moulding can be performed with a host of materials mainly including metals for which the process is called die-casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. That article continues to capture eyeballs getting as manyand sometimes morepage views than current content.

This means shorter cycle times resulting in more parts produced per hour and lower production cost. A 36-year-old male machine operator died when he was crushed between the platens of a 3200-. Thus we refer to it as an injection molding attachment for a drill press.

3200 Ton horizontal injection molding machine was operated in manual mode. He has 40 years of injection molding experience starting out as a machine operator. Be part of the community.

Build Make Plastic Injection Molding Drill Press Attachment Diy How To Plastic Injection Molding Plastic Injection Plastic Moulding

1 300 Hobby Business Plastic Injection Molding Machine Molder Press Free Mold Plastic Injection Moulding Machine Plastic Moulding Plastic Injection Molding

Homemade Plastic Injection Molding Machine Plastic Injection Plastic Injection Moulding Machine Diy Molding

Desktop Injection Molding Machine Injection Machine Plastic Injection Molding Plastic Moulding

Make Your Own Injection Molding Machine Make Plastic Injection Molding Diy Molding Molding

Plastic Injection Moulding Machine Model 4 Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Homemade Injection Molding Machine Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

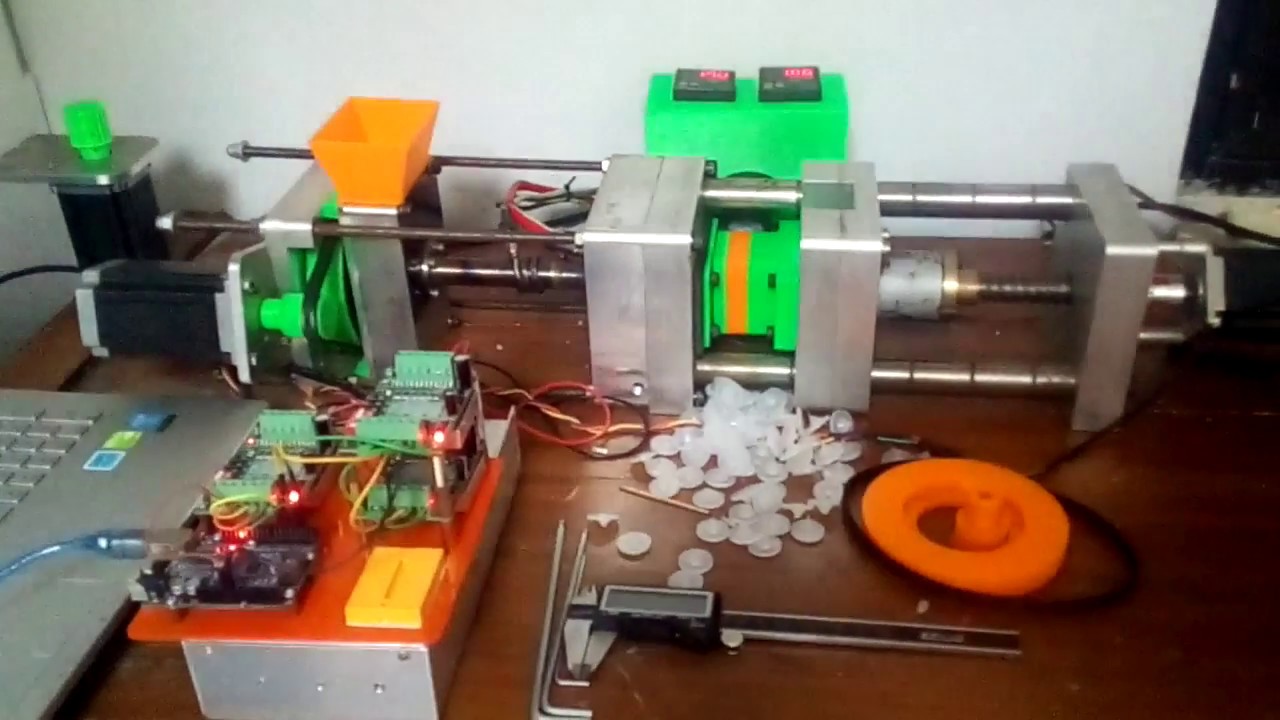

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Micro Injection Molding Machine Plastic Injection Molding Injection Machine Plastic Injection

Diy Injection Molding Plastic Injection Molding Injection Moulding Plastic Injection

How To Use An Injection Molding Machine The Gs 5t Edition Youtube Diy Molding Plastic Injection Molding Plastic Moulding

Model 150a Plastic Injection Machine Plastic Injection Plastic Moulding Injection Molding Machine

Make Your Own Injection Molding Machine Make Diy Molding Diy Projects Homemade Machine

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

Electronics Cars Fashion Collectibles Coupons And More Diy Molding Plastic Injection Molding Plastic Moulding

Pin By Arbi Oussama On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Mould Design Injection Moulding